Bending Sheet Metal

Bending Sheet Metal - The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless some. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular. In its simplest form, the work piece is formed between two dies, as seen in the. It guarantees simplicity and it is an efficient way of forming new. Sheet metal bending is an effective way of making products with different shapes used for different processes. To bend your sheet metal with a vise and hammer, you will need: Web 1 gather your materials. Web when a sheet metal part is bent, it physically gets bigger. Having the right tools on hand will help this process go smoothly and quickly. Web sheet metal bending.

Web when a sheet metal part is bent, it physically gets bigger. It guarantees simplicity and it is an efficient way of forming new. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless some. 2 wooden or metal form blocks block of. In its simplest form, the work piece is formed between two dies, as seen in the. Web 1 gather your materials. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular. Web bending is one of the most common sheet metal fabrication operations. Having the right tools on hand will help this process go smoothly and quickly. To bend your sheet metal with a vise and hammer, you will need:

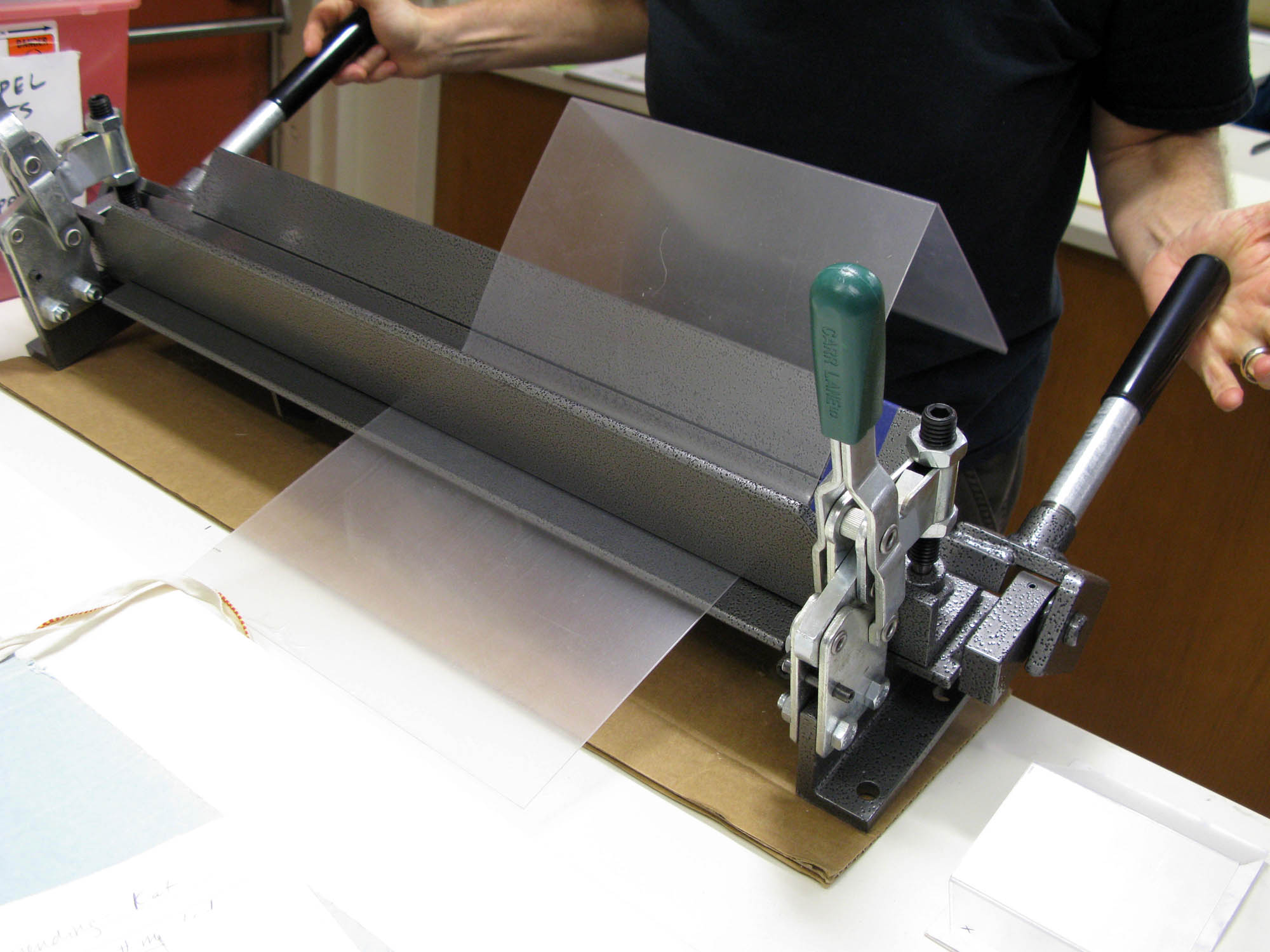

Having the right tools on hand will help this process go smoothly and quickly. Web sheet metal bending. In its simplest form, the work piece is formed between two dies, as seen in the. Web bending is one of the most common sheet metal fabrication operations. Web brake press the brake press is a tool that has been used for many years in traditional fabrication shops all over the world. It guarantees simplicity and it is an efficient way of forming new. Sheet metal bending is an effective way of making products with different shapes used for different processes. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular. To bend your sheet metal with a vise and hammer, you will need: The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless some.

Sheet Metal Design Tips For Bending Xometry Europe

Sheet metal bending is an effective way of making products with different shapes used for different processes. To bend your sheet metal with a vise and hammer, you will need: 2 wooden or metal form blocks block of. Web bending is one of the most common sheet metal fabrication operations. Web sheet metal bending.

Things to Consider About Sheet Metal Bending in the Design Process

Web 1 gather your materials. Sheet metal bending is an effective way of making products with different shapes used for different processes. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless some. It guarantees simplicity and it is an efficient way of forming new. Web when.

Metal Guidelines Methods of Sheet Metal Bending

Web when a sheet metal part is bent, it physically gets bigger. To bend your sheet metal with a vise and hammer, you will need: 2 wooden or metal form blocks block of. Web bending is one of the most common sheet metal fabrication operations. Web 1 gather your materials.

Premium Photo The process of bending sheet metal on a hydraulic

Web when a sheet metal part is bent, it physically gets bigger. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless some. Having the right tools on hand will help this process go smoothly and quickly. In its simplest form, the work piece is formed between.

The sheet bending

It guarantees simplicity and it is an efficient way of forming new. Web 1 gather your materials. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless some. Web when a sheet metal part is bent, it physically gets bigger. Web bending is one of the most.

Spencer Research Library Blog » Vivak Exhibition Cradles

Web bending is one of the most common sheet metal fabrication operations. It guarantees simplicity and it is an efficient way of forming new. 2 wooden or metal form blocks block of. Web when a sheet metal part is bent, it physically gets bigger. Also known as press braking , flanging, die bending, folding and edging , this method is.

The fineart of sheet metal bending EngineeringClicks

Sheet metal bending is an effective way of making products with different shapes used for different processes. In its simplest form, the work piece is formed between two dies, as seen in the. Web bending is one of the most common sheet metal fabrication operations. Web brake press the brake press is a tool that has been used for many.

Precise Metal Bending Services By Elemet Manufacturing

Sheet metal bending is an effective way of making products with different shapes used for different processes. In its simplest form, the work piece is formed between two dies, as seen in the. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular. It guarantees simplicity.

Bildergebnis für sheet metal bending Erwin Pinterest Metal

Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular. Web when a sheet metal part is bent, it physically gets bigger. 2 wooden or metal form blocks block of. Web brake press the brake press is a tool that has been used for many years.

The art of sheet metal bending

2 wooden or metal form blocks block of. In its simplest form, the work piece is formed between two dies, as seen in the. Web 1 gather your materials. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless some. Also known as press braking , flanging,.

Also Known As Press Braking , Flanging, Die Bending, Folding And Edging , This Method Is Used To Deform A Material To An Angular.

2 wooden or metal form blocks block of. Web 1 gather your materials. Having the right tools on hand will help this process go smoothly and quickly. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless some.

Web Sheet Metal Bending.

In its simplest form, the work piece is formed between two dies, as seen in the. Web brake press the brake press is a tool that has been used for many years in traditional fabrication shops all over the world. Sheet metal bending is an effective way of making products with different shapes used for different processes. Web bending is one of the most common sheet metal fabrication operations.

It Guarantees Simplicity And It Is An Efficient Way Of Forming New.

To bend your sheet metal with a vise and hammer, you will need: Web when a sheet metal part is bent, it physically gets bigger.