Bending Steel Sheet

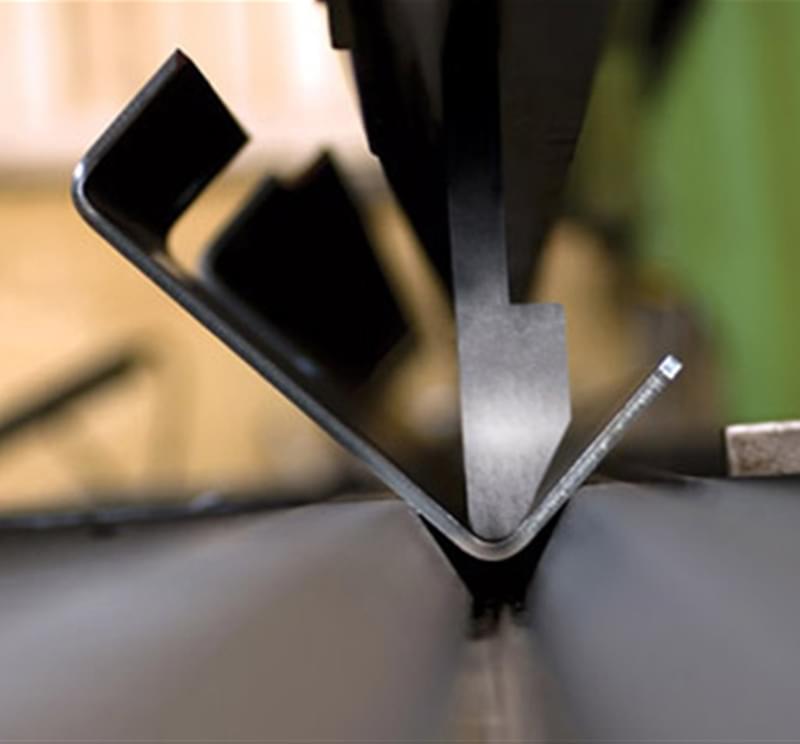

Bending Steel Sheet - This is due to the flexibility of the tooling, and the high. Web from 0.5mm sheet up to 20mm plate and beyond. The fundamentals of how to bend metal grain direction in metal bending. In bottoming, the sheet is forced against the v opening in the bottom tool.

Web from 0.5mm sheet up to 20mm plate and beyond. The fundamentals of how to bend metal grain direction in metal bending. This is due to the flexibility of the tooling, and the high. In bottoming, the sheet is forced against the v opening in the bottom tool.

The fundamentals of how to bend metal grain direction in metal bending. Web from 0.5mm sheet up to 20mm plate and beyond. In bottoming, the sheet is forced against the v opening in the bottom tool. This is due to the flexibility of the tooling, and the high.

Shri Balaji Steel Sheet Metal Bending Parts at Rs 80/piece in Faridabad

Web from 0.5mm sheet up to 20mm plate and beyond. In bottoming, the sheet is forced against the v opening in the bottom tool. The fundamentals of how to bend metal grain direction in metal bending. This is due to the flexibility of the tooling, and the high.

Custom Sheet Metal Bending Custom Rolled Sheet Metal

In bottoming, the sheet is forced against the v opening in the bottom tool. The fundamentals of how to bend metal grain direction in metal bending. This is due to the flexibility of the tooling, and the high. Web from 0.5mm sheet up to 20mm plate and beyond.

Bending Die and Forcer Metal bending tools, Welding projects, Metal

The fundamentals of how to bend metal grain direction in metal bending. In bottoming, the sheet is forced against the v opening in the bottom tool. This is due to the flexibility of the tooling, and the high. Web from 0.5mm sheet up to 20mm plate and beyond.

Things to Consider About Sheet Metal Bending in the Design Process

This is due to the flexibility of the tooling, and the high. In bottoming, the sheet is forced against the v opening in the bottom tool. Web from 0.5mm sheet up to 20mm plate and beyond. The fundamentals of how to bend metal grain direction in metal bending.

Sheet metalworking Minifaber

This is due to the flexibility of the tooling, and the high. In bottoming, the sheet is forced against the v opening in the bottom tool. Web from 0.5mm sheet up to 20mm plate and beyond. The fundamentals of how to bend metal grain direction in metal bending.

Sheet Metal Design Tips For Bending Xometry Europe

The fundamentals of how to bend metal grain direction in metal bending. In bottoming, the sheet is forced against the v opening in the bottom tool. This is due to the flexibility of the tooling, and the high. Web from 0.5mm sheet up to 20mm plate and beyond.

Homemade sheet metal bending YouTube

This is due to the flexibility of the tooling, and the high. The fundamentals of how to bend metal grain direction in metal bending. Web from 0.5mm sheet up to 20mm plate and beyond. In bottoming, the sheet is forced against the v opening in the bottom tool.

The sheet bending

This is due to the flexibility of the tooling, and the high. Web from 0.5mm sheet up to 20mm plate and beyond. In bottoming, the sheet is forced against the v opening in the bottom tool. The fundamentals of how to bend metal grain direction in metal bending.

Precise Metal Bending Services By Elemet Manufacturing

The fundamentals of how to bend metal grain direction in metal bending. Web from 0.5mm sheet up to 20mm plate and beyond. This is due to the flexibility of the tooling, and the high. In bottoming, the sheet is forced against the v opening in the bottom tool.

Premium Photo The process of bending sheet metal on a hydraulic

The fundamentals of how to bend metal grain direction in metal bending. Web from 0.5mm sheet up to 20mm plate and beyond. In bottoming, the sheet is forced against the v opening in the bottom tool. This is due to the flexibility of the tooling, and the high.

The Fundamentals Of How To Bend Metal Grain Direction In Metal Bending.

Web from 0.5mm sheet up to 20mm plate and beyond. In bottoming, the sheet is forced against the v opening in the bottom tool. This is due to the flexibility of the tooling, and the high.